Squeegee Selection

Having the right squeegee is integral to achieving the best

print possible for your silkscreen.

There are several factors that affect the performance of

your squeegee blade. Abrasion against the mesh slowly

blunts the squeegee reducing the ability to shear ink from

the screen. Solvents will also degrade the squeegee

material, this is mainly seen in Solvent

based inks and UV inks. These can cause

the blade to soften or swell on the

press which can affect print quality.

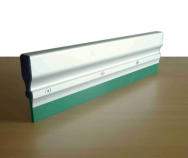

Squeegees are commonly supplied in 3

hardnesses and 2 section sizes. The values of hardness are

typically 60-65 Shore (Red), 70-75 Shore (Green) and 80-85

Shore (Blue). Usually the substrate and

screen mesh determine the hardness

required. If the substrate is an irregular

or rough surface and requires a coarse

mesh a softer squeegee is required (60-

65 Shore Red). If the substrate has a

smooth surface and a high mesh count

is being used a harder squeegee is

required (80-85 Shore Blue). The most common squeegee

used is 70-75 Shore Green as this blade is rigid yet soft

enough to adapt to the contours of the screen.

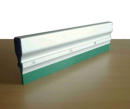

The two most common profile size used in screen printing

are 50mm x 9mm and 25mm x 5mm. The 50mm x 9mm

profile is used for general screen printing

(glass, graphics and textiles). The 25mm x 5mm profile is

used for bottle, cd printing and high speed automatic

presses.

In this section we aim to answer any questions you may

have regarding the frame, mesh, squeegee or artwork you

require.

FAQ’s

© Copyright, All Rights Reserved - Buckleberry Ltd.

Squeegee Selection

Having the right squeegee is integral to achieving the best print

possible for your silkscreen.

There are several factors that affect the performance of your

squeegee blade. Abrasion against the mesh slowly blunts the

squeegee reducing the ability to shear

ink from the screen. Solvents will also

degrade the squeegee material, this is

mainly seen in Solvent based inks and UV

inks. These can cause the blade to soften

or swell on the press which can affect

print quality.

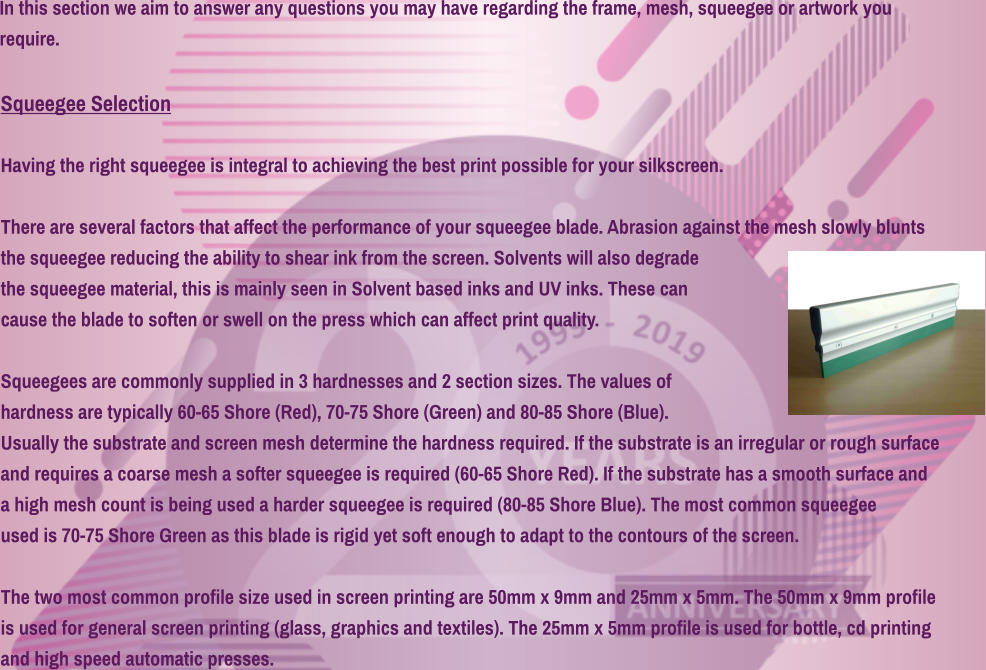

Squeegees are commonly supplied in 3 hardnesses and 2 section

sizes. The values of hardness are typically 60-65 Shore (Red),

70-75 Shore (Green) and 80-85 Shore (Blue). Usually the substrate

and screen mesh determine the hardness required. If the

substrate is an irregular or rough surface and requires a coarse

mesh a softer squeegee is required (60-65 Shore Red). If the

substrate has a smooth surface and a high mesh count is being

used a harder squeegee is required (80-85 Shore Blue). The most

common squeegee used is 70-75 Shore Green as this blade is

rigid yet soft enough to adapt to the contours of the screen.

The two most common profile size used in screen printing are

50mm x 9mm and 25mm x 5mm. The 50mm x 9mm profile is used

for general screen printing (glass, graphics and textiles). The

25mm x 5mm profile is used for bottle, cd printing and high speed

automatic presses.

In this section we aim to answer any questions you may have

regarding the frame, mesh, squeegee or artwork you require.

FAQ’s